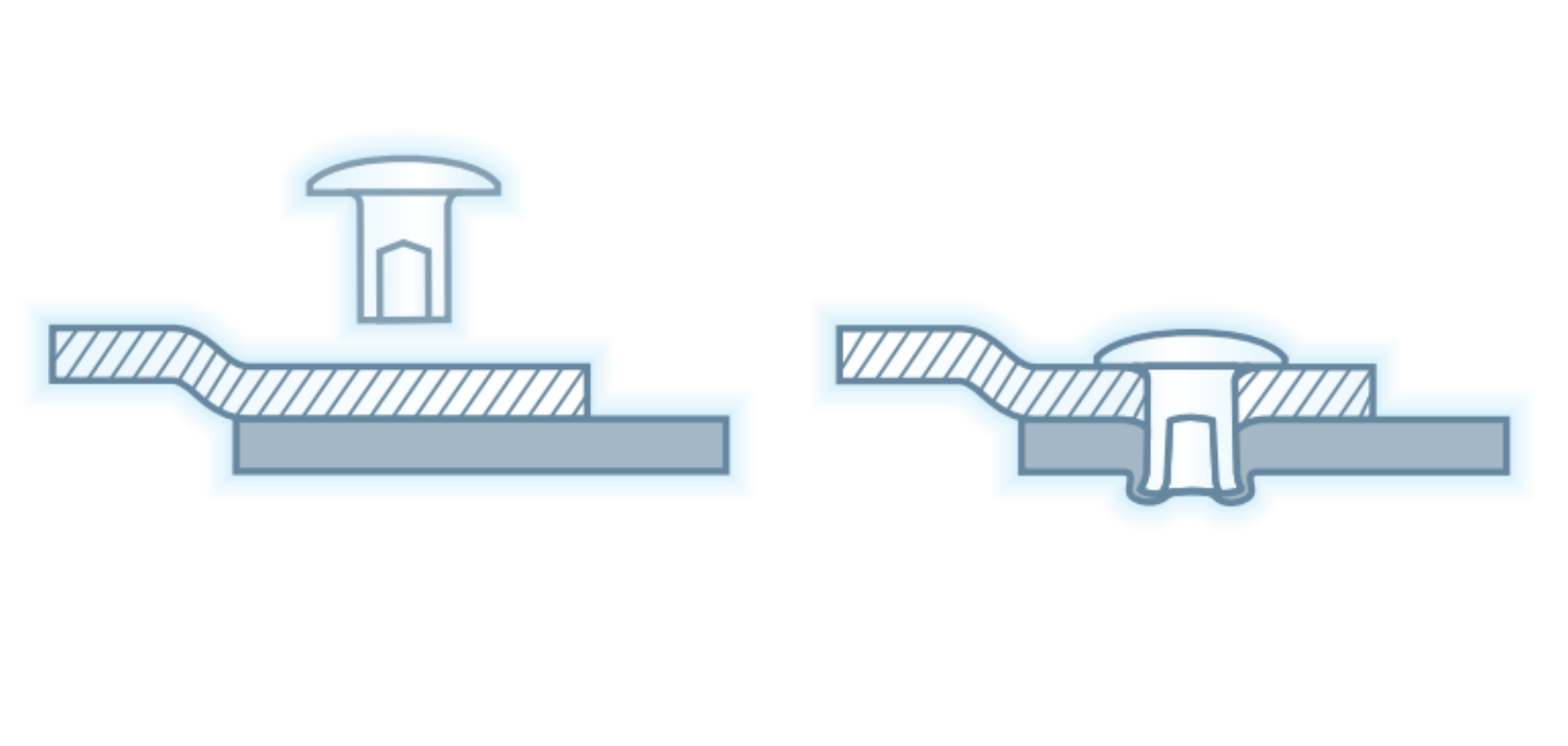

Self-Piercing Rivets

Improved Productivity

Improved productivity may be achieved in many cases by the use of exceptionally strong self-piercing rivets. Rivet assembly becomes more economical because pre-punched holes are eliminated. Your application may be a perfect candidate for self-piercing rivets. National Rivet has the expertise to design the ideal rivet and machine to meet your needs.

Steel, stainless steel, aluminum, brass, and certain plastics and fibers can be joined successfully with self-piercing rivets, resulting in a good uniform appearance and a strong and consistent joint.

National Rivet has a complete line of rivet setters ideally suited for metal piercing rivets. Custom anvil arms are available to reach into narrow openings. A 1/8″ diameter rivet can be set as close as 3/16″ to a side wall or flange. Refer to the Machines section of this catalog for further information, or contact our engineering department for help on your particular needs.

Product Specs

Material hardness, thickness, and number of layers determine metal piercing ability. The table shows steel rivets and is based on typical sheet metal applications.