Rivets & Fasteners

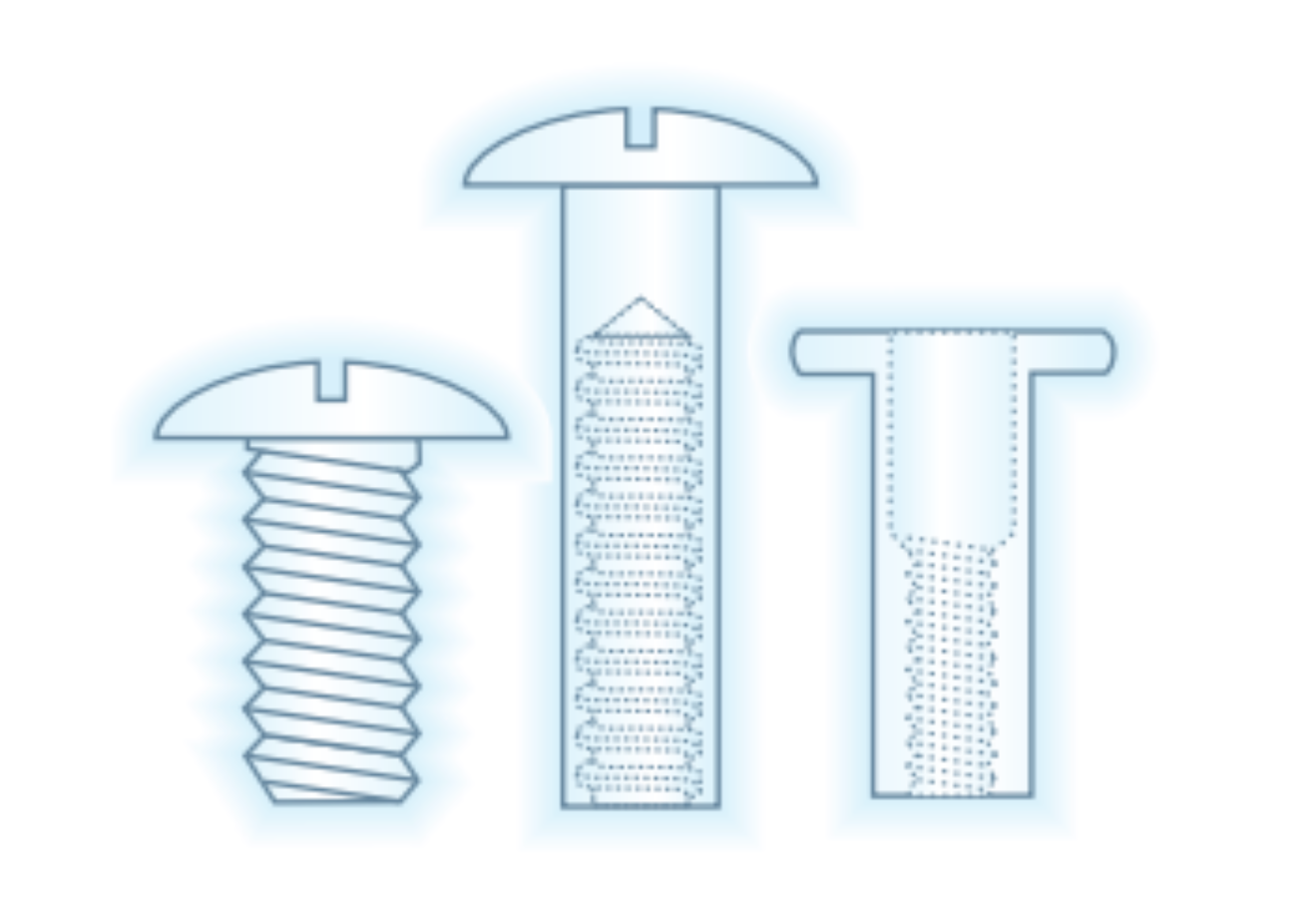

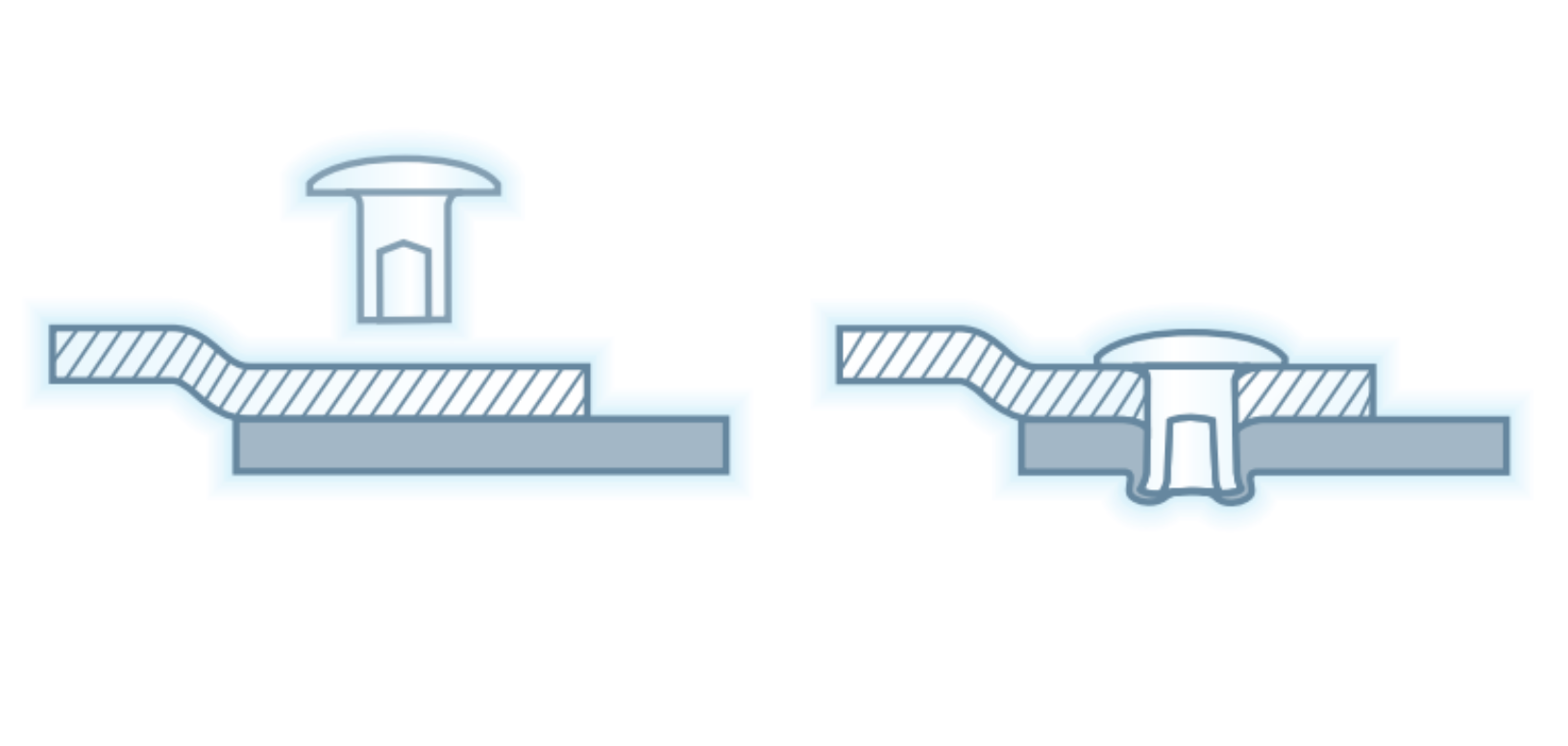

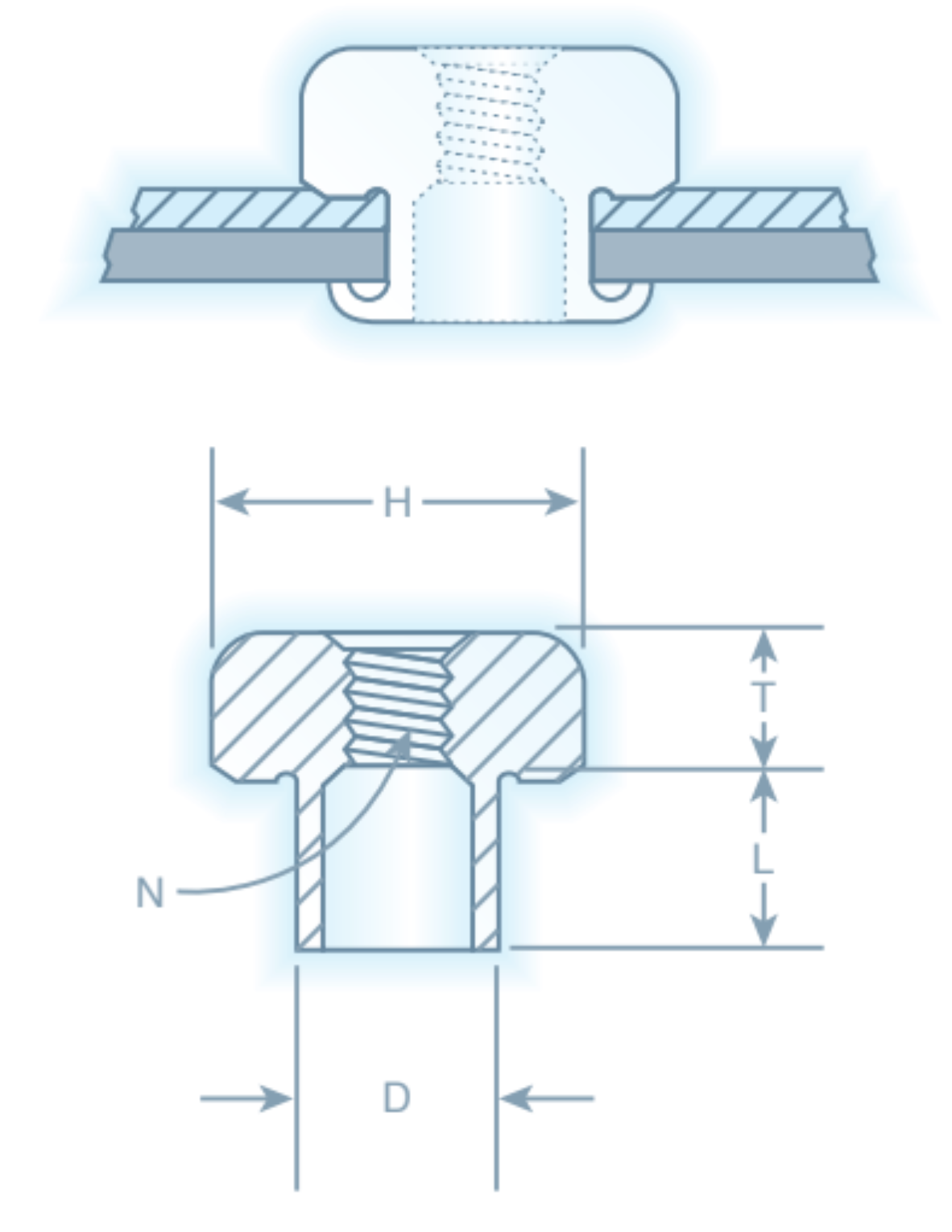

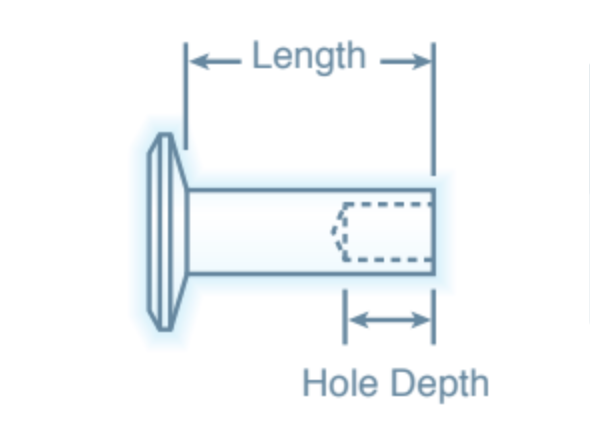

Rivets and Finishing Capabilities

Explore our wide range of rivets, high-quality finishing, and in-house plating options to best fit your unique application and requirements.

Finishing Options

National Rivet’s ‘Finishing Operations’ are second to none in the industry. In addition to cleaning, degreasing, and tumbling, rivets may be waxed, oiled, hardened, enameled, lacquered, heat treated, chemical coated or plated. Using state-of-the-art equipment, our finishes are always the highest quality.

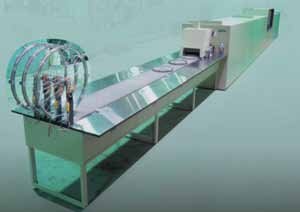

In-House Plating

Quality control is maintained throughout all operations in the finishing department. Our computer-controlled x-ray examination of rivets is the most accurate non-destructive method for determining plating thickness.

Available finishes and chemical coatings

National Rivet can help you select the proper finish to best suit your application.

Zinc

Copper

Brass

Nickel

Tin

Anodize

(Aluminum)

Iridite

(Aluminum)

Silver

Chrome

Phosphate Coatings

Black Oxide

(Steel, Brass, Stainless Steel)

Electroless Nickel

(Steel)

Teflon©

Dry Film Lubricants

Painted Heads

(Enamel, Powder)

Chromate Conversion

(Clear, Yellow, Black)

Parkerize

Black Ebonol©

(Steel)

Identification Dyeing

Heat Treating

Our state-of-the-art heat treating facility combines precision control of temperature and atmosphere to assure uniform quality. Various methods are utilized to meet your specific heat treating requirements.

Materials

National Rivet utilizes all metals suitable for cold heading. Most stock is inventoried in our warehouse and is available for immediate production.

All other cold heading metals available upon request.