Rivet Machine Options

Special Arms

Customized Fixtures

Feeding Devices

Compensators

Special Arms

All rivet setting machines can be equipped with special arms, anvil holders, goosenecks and anvils when necessary.

Whenever possible National engineers will recommend a standard arm. However, if it is not possible to do the riveting with a standard arm, a custom-designed arm and anvil holder can be made to meet the requirements of the job. Special goosenecks and anvils can also be designed if needed.

National engineers have many years of experience in designing and manufacturing riveting equipment and can solve any special fastening or assembly problem your company has.

Customized Fixtures

Positioning Fixtures

Positioning fixtures are stationary fixtures designed to hold one or more components in place for positive alignment during riveting.

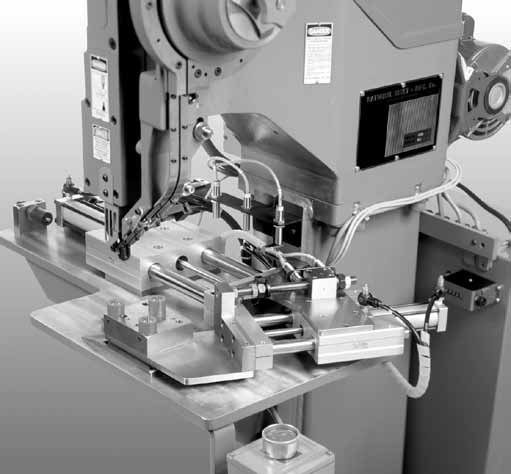

Moveable Fixtures

Moveable fixtures can improve production efficiency and operator safety. Fixtures can be engineered to move manually or automatically and can feature multiple positive stops or interlocks. This allows a single machine to set multiple rivets in a part or component.

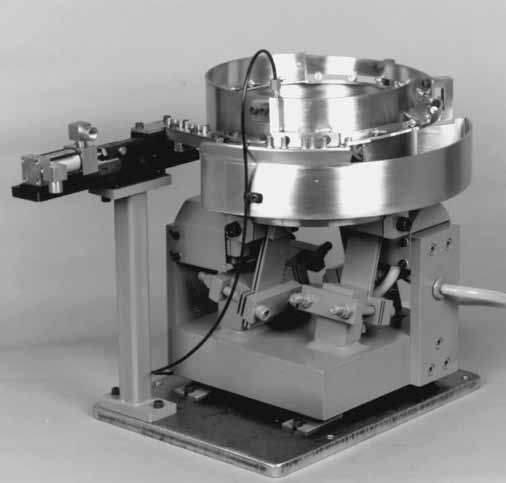

Feeding Devices

National has used vibratory feeders to deliver rivets, unusually shaped cold headed parts, washers, electrical contacts, coil springs, spacers and other parts. Transfer to the machine can be via slide, tube or automatic placement device.

Compensators

A compensating device allows a riveting machine to accommodate varying work thicknesses. This is done by allowing the anvil to move vertically as the rivet is driven down through the work. The anvil is supported by a force, either spring pressure or air pressure, which can be adjusted so that each rivet is set the same regardless of the thickness of the parts being riveted.

View Our Rivet Machines

National Rivet’s rivet setting machines meet the needs of nearly any fastening application challenge, or requirement.