Precision Machines for Small Rivets

Features

Explore the key features that make our precision machines ideal for effortlessly handling small parts.

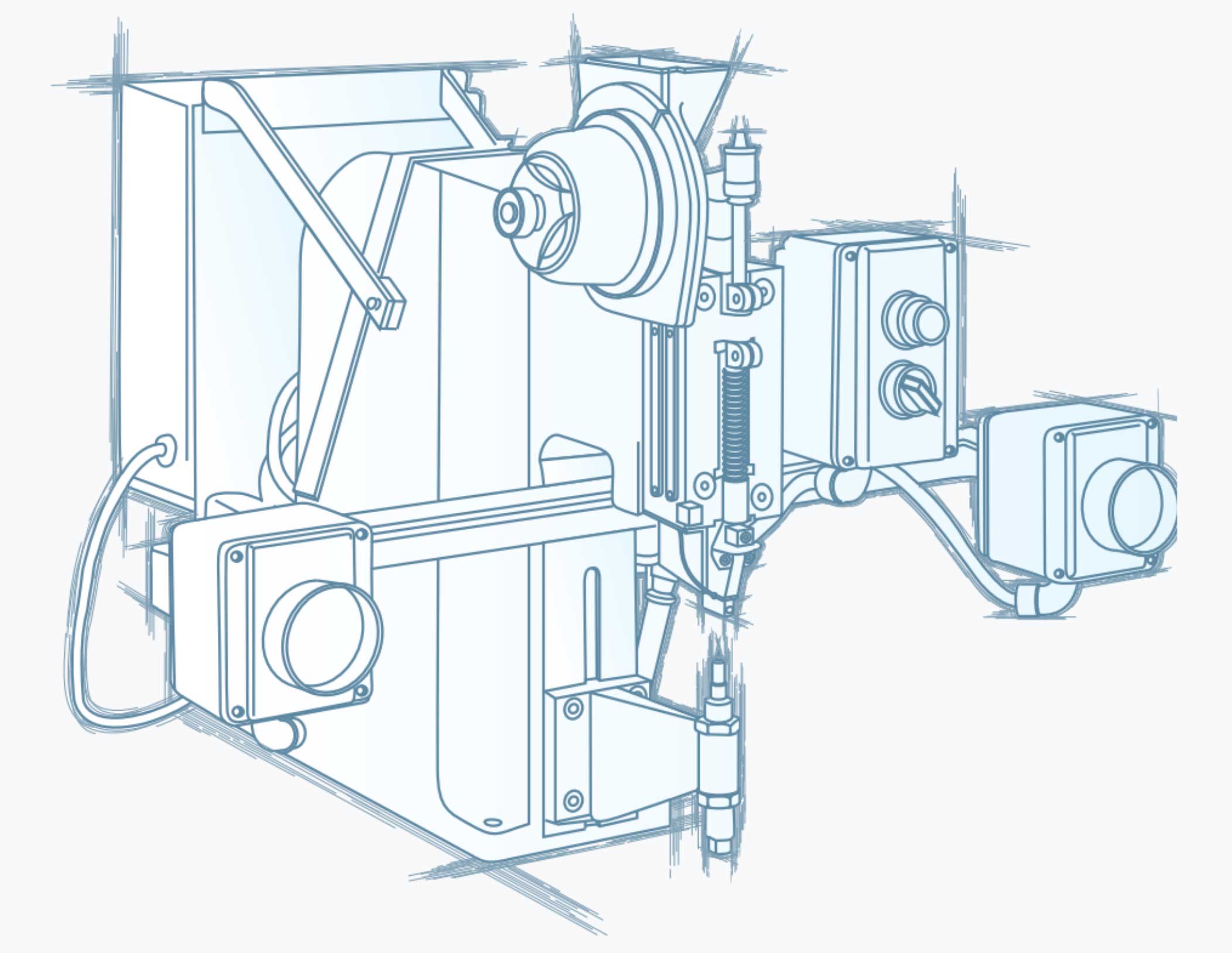

Both models feature a nose block assembly which can be removed and replaced with a unit tooled for a different rivet.

Like all National Riveters, these models feature the Advancing Jaw Carrier to reduce jaw and driver wear and ensure dependable feeding of rivets.

Model B is electric, with a 1/6 H.P., 1140 RPM motor. The crank pin and connecting rod mechanism gives this model a gentle but powerful setting force.

Model BA is air operated, making it the ideal machine for riveting fragile parts, brittle materials and parts that vary in thickness, without distortion or breakage.

Model BA rivet setting pressure is adjustable down to 20 P.S.I.

Approximate cycle time for the B is 1/3 second; 1 second for the BA.

Each model can be customized to your specific needs and requirements.

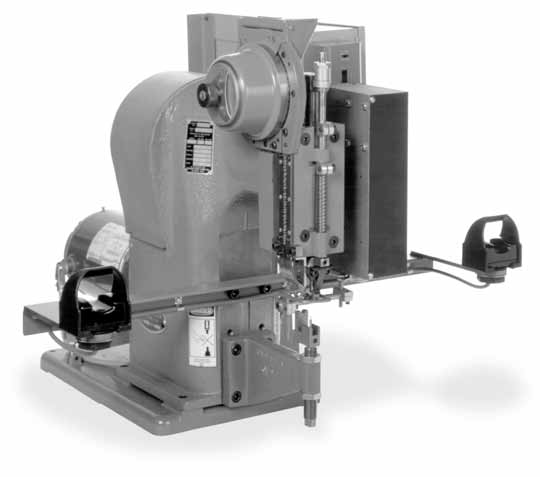

Model B Electric Machine

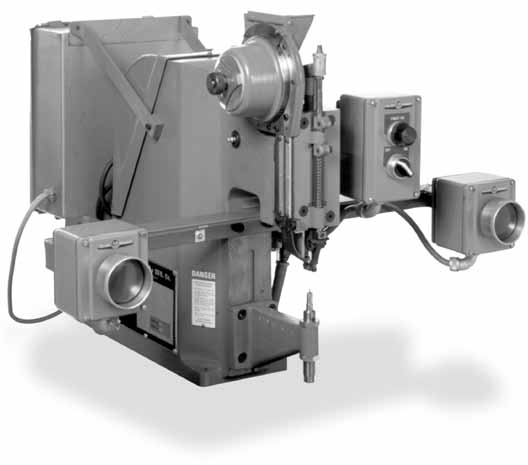

Model BA Pneumatic Machine

Model B Electric Machine

Product Specs

Optional dual safety switches are shown.

.125" dia. x .375" length, max.

60 cy., 1 ph., 115v Std.

Opt.: 1/4 H.P., 1140 R.P.M.

220/440/480v, 3 ph., 60 cy.

Model BA Pneumatic Machine

Product Specs

Optional safety switches are shown.

Max.: .125" dia. x .375" length

Rivet Tools & Accessories

Investing in quality riveting accessories is a proven method for increasing efficiency. In fact, many people blame problems on their rivets or rivet setters, when the real culprit is worn or inadequate tools and accessories. As an integrated supplier, our engineers can quickly spot system deficiencies and recommend a new, more productive riveting solution.