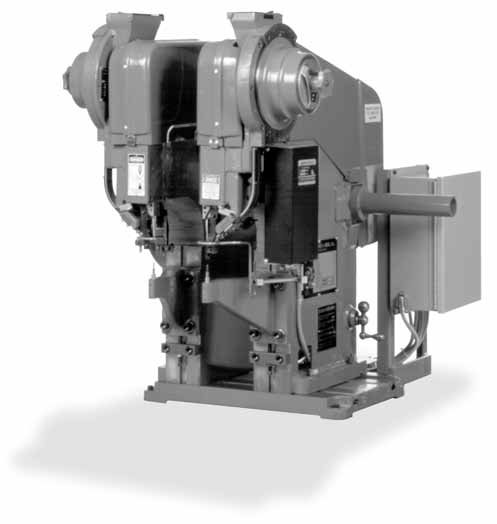

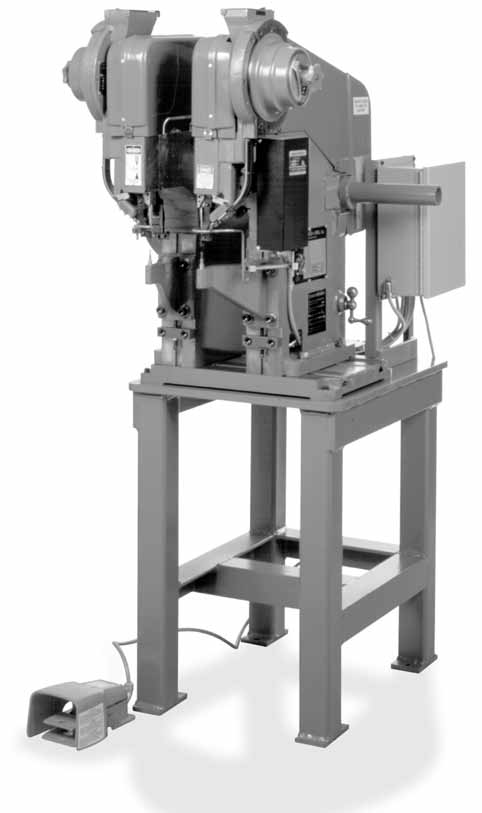

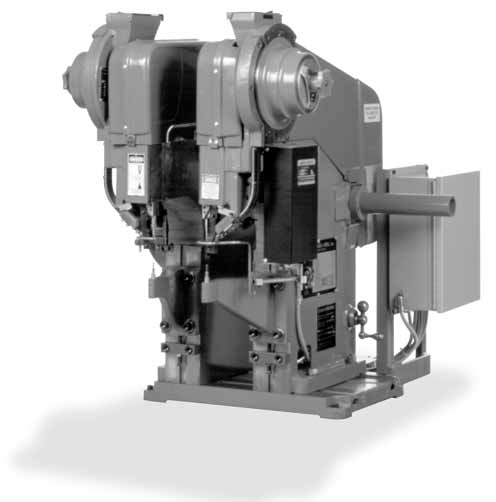

Electro-Mechanical Dual Head

Features

One of the riveter heads is stationary on the base, while the other head may be moved to establish the desired center distance.

An adjusting crank changes center distance easily. The standard range of adjustment is from 3/8″ to 8″. An optional wide base is available to allow up to 16″ between anvils.

The 2400 Series handles semi-tubular steel rivets up to .125″ in diameter. 2600 Series is capable of setting larger standard, semi- tubular steel rivets – up to .186″ in diameter.

These models feature an 8″ throat depth, a single revolution heavy duty clutch and an electric motor driven flywheel that powers an eccentric and connecting rod mechanism. This mechanism is linked to a rocker arm and plunger assembly which delivers the setting force to the rivet. The eccentric drive gives a smooth and gentle setting motion, yet is powerful and positive in rivet setting height. Riveting cycle time is 1/3 second.

The modern, welded steel construction ensures long service life, minimum maintenance and quiet operation.

Each model can be customized to your specific needs and requirements. For model comparison specs, see pages 34 and 35. For optional accessories, please see pages 40 and 41. For safety information, see page 46.

Model 2400F

Model 2400B

Model 2600F

Model 2600B

Model 2400F

Product Specs

60 cy., 1 ph., 115v Std.

Opt.: 220/440/480v, 3 ph., 60 cy.

model 2400B

Product Specs

60 cy., 1 ph., 115v Std.

Opt.: 220/440/480v, 3 ph., 60 cy.

Model 2600F

Product Specs

60 cy. Std.; Opt. 220/440/480V,

3 ph., 60 cy.

Model 2600B

Product Specs

60 cy. Std.; Opt. 220/440/480V,

3 ph., 60 cy.

Rivet Tools & Accessories

Investing in quality riveting accessories is a proven method for increasing efficiency. In fact, many people blame problems on their rivets or rivet setters, when the real culprit is worn or inadequate tools and accessories. As an integrated supplier, our engineers can quickly spot system deficiencies and recommend a new, more productive riveting solution.