Rivet Machines

Custom Engineered Rivet Setting Machines

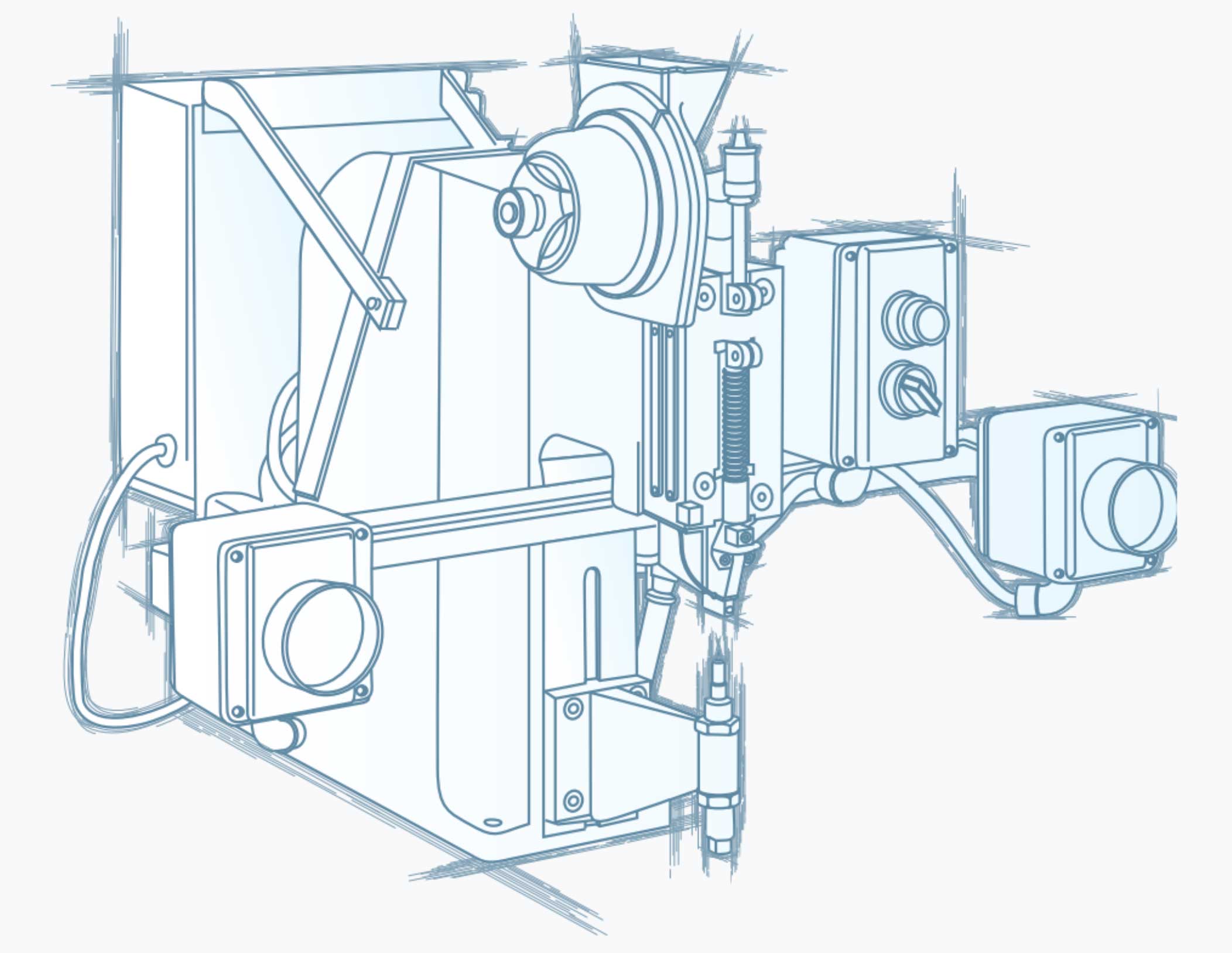

National Rivet welcomes orders for custom-engineered rivet setting machines. Our engineers can design the ideal riveter or rivet setting system to fasten intricate shapes, extremely small or large pieces, and complicated assemblies. We can also adapt standard machines by equipping them with special arms, feeding devices for rivets and parts, customized fixtures, and compensators.

Improve productivity

Reduce cycle times

Replace more costly fastening methods

Lower scrap rates/improve consistency

Compensate for operator fatigue

Improve workflow

Increase assembly flexibility

(multiple tasks for one machine)

Automate assembly operations more effectively

Create a more robust fastener / fastening system

Meet corporate goals

(kaizen, 5S, ISO, safety, etc.)

Engineered Machine Applications

Let’s create a unique fastening solution for you today!

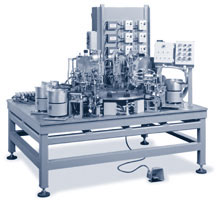

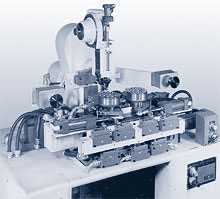

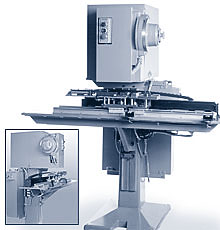

10-Unit Rivet Machine

Three model B rivet setters are used with a twelve fixture index table and four vibratory feeder placement devices. Small, hard to handle parts are automatically placed on each fixture and sensed for presence before the contacts are set. If any part or contact is missing, the machine will stop. An air jet unloads the completed assembly.

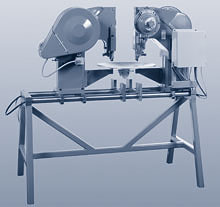

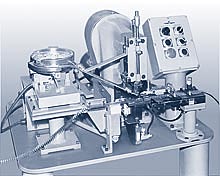

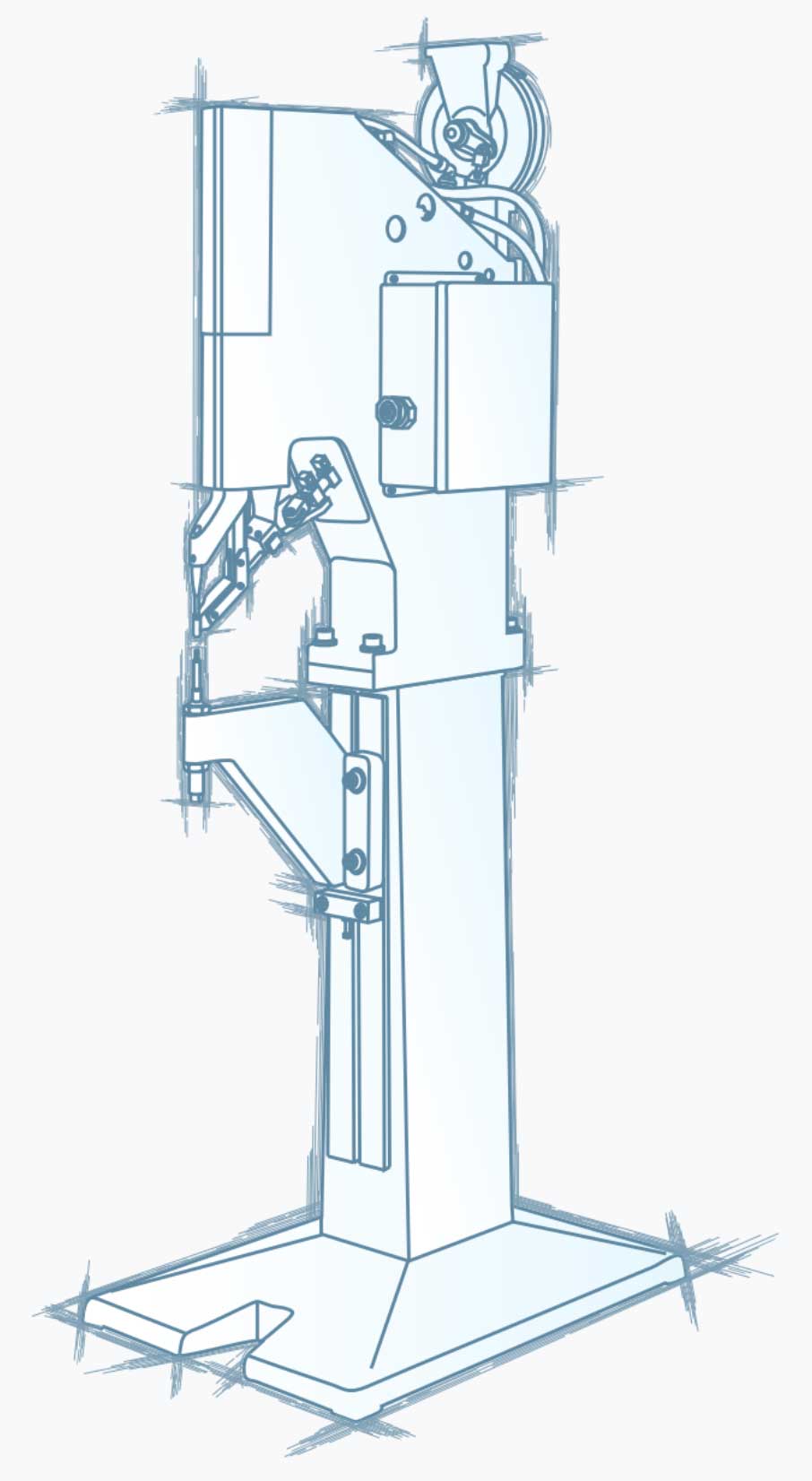

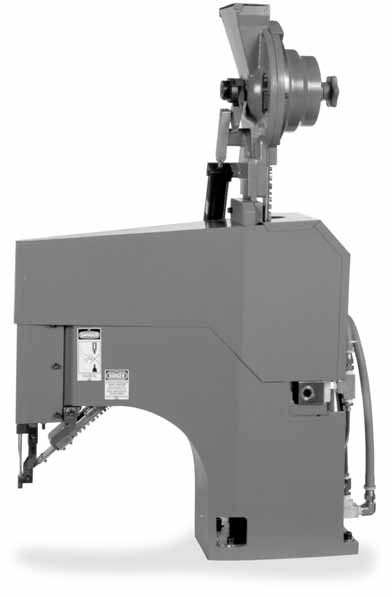

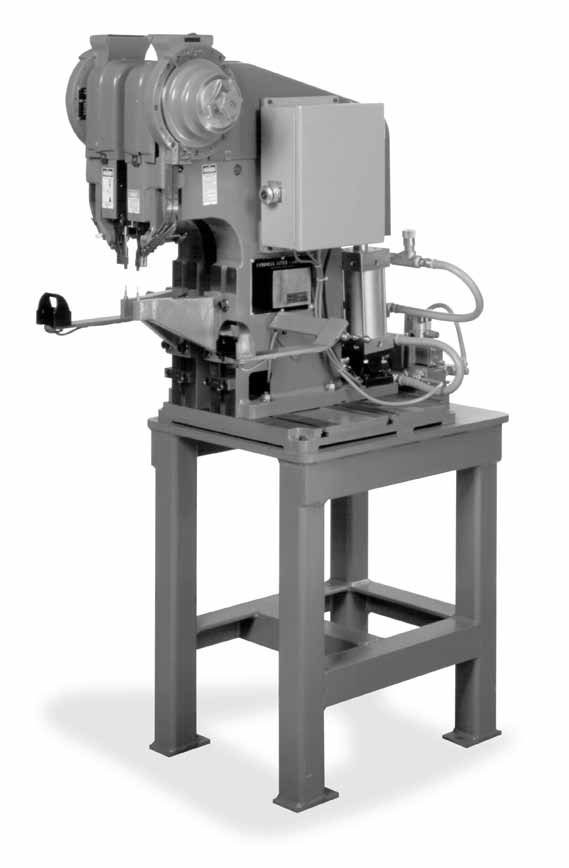

Mounted 500B

Two Model 500B’s mounted on a special base to rivet an 18” satellite dish. The parts to be riveted are positioned in a locating fixture and the riveting machines are adjustable to accommodate parts of various sizes. A version of this machine is used to assemble loose leaf binders.

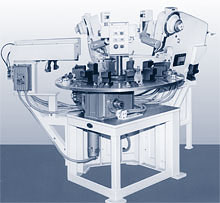

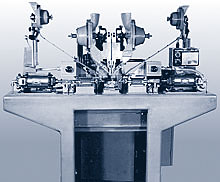

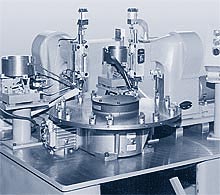

Model 2610 and 2620 Riveters

Model 2610 and 2620 Riveters are mounted at 15° angles to a 48 inch 12 station index table, to set 2 rivets in a tubular assembly. Sensors indicate part presence and low rivet supply. Pick off unit automatically removes completed assembly.

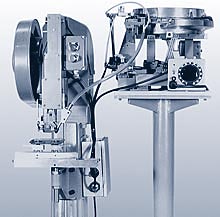

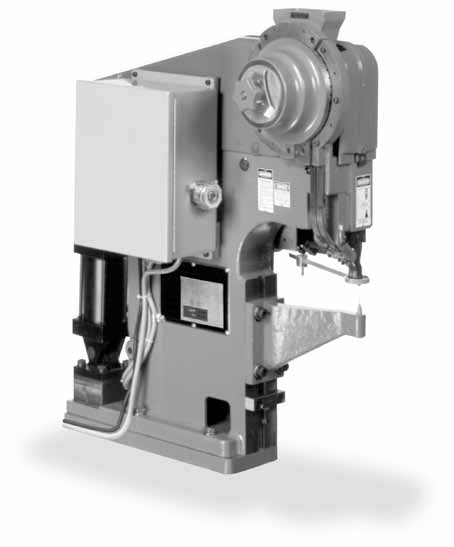

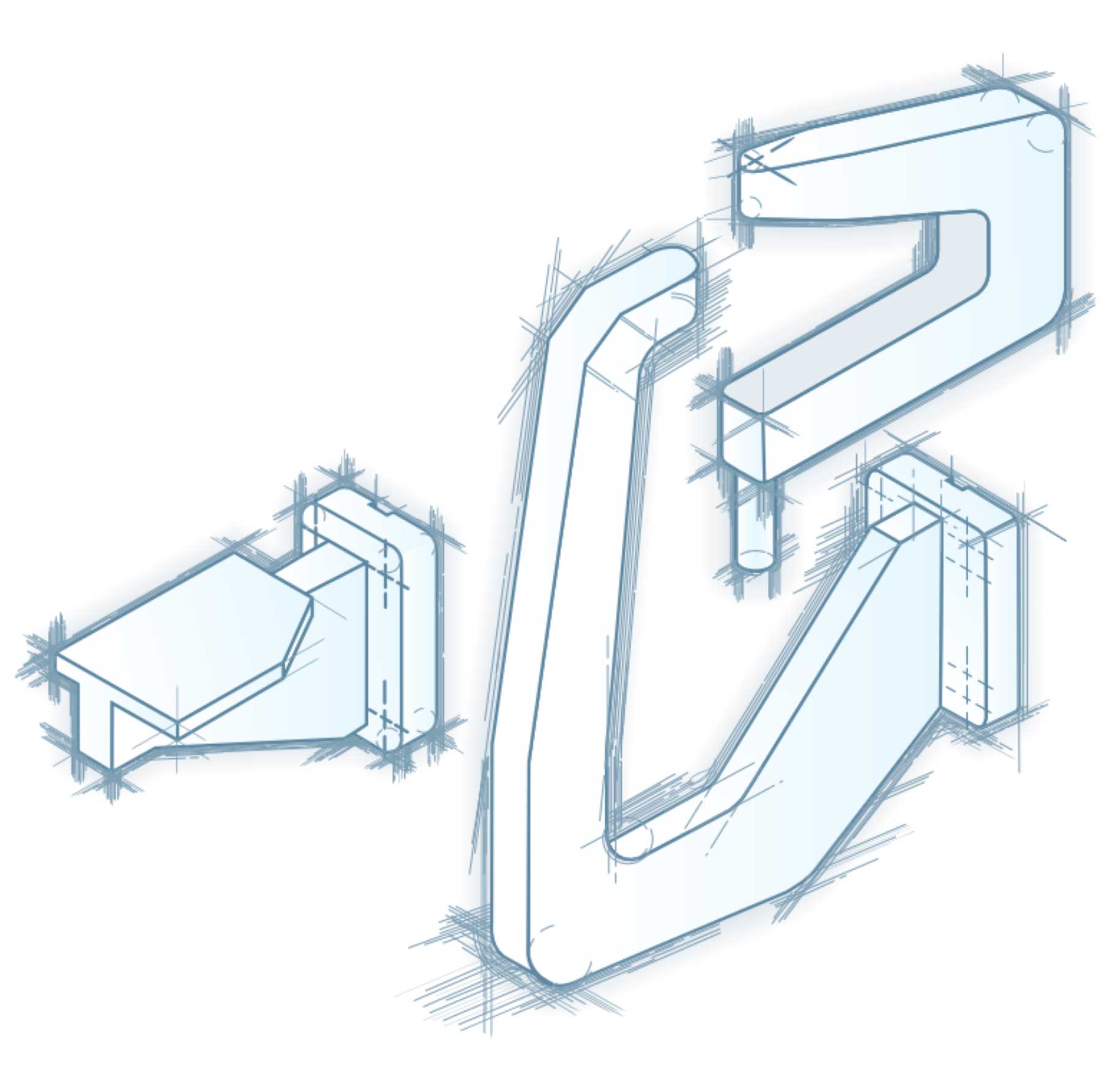

Underfeed Application

Special under-feed for a large shoulder rivet makes it possible to obtain the economies of riveting even though there is insufficient clearance to drive a rivet in the conventional manner.

Tube Feed Attach

Unusual tube feeding attachment and shuttle table speed the assembly of battery terminal covers. A special vibratory feeder orients and discharges a specially-designed collar-type fastener that becomes a terminal post.

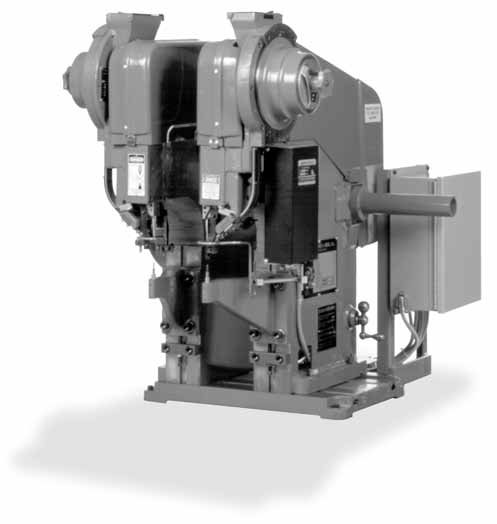

Ball Bearing Retainer

Rivets are inserted in ball bearing retainers at the rate of up to 7000 per hour by this National machine. Retainers are placed on indexing nests on each side of the machine and the nests are positioned automatically under the Model B Riveter.

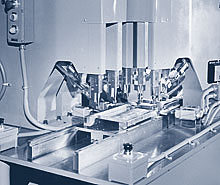

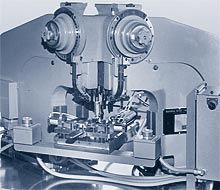

Application of 4 Riviters

This example of a specially designed National Riveter sets four very small rivets at the same time, two vertically, and two horizontally. It rivets the cover and the clip of automotive ash trays in a single operation.

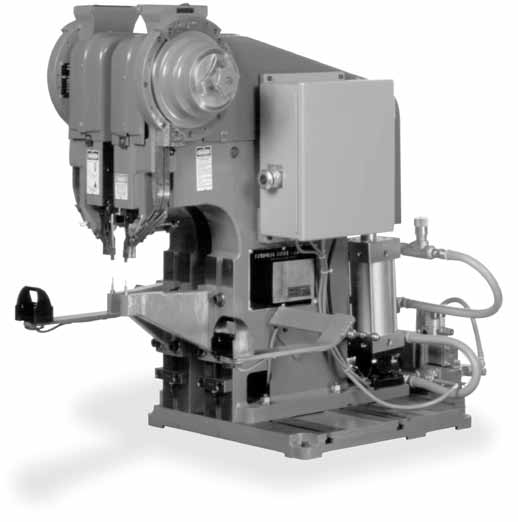

1400 Air Heads

Five National Model 1600 Offset air heads mounted on a special base so that the head on the right may be swiveled for use as a single riveter. The machine will set four or five rivets as required.

Application 10 Self-Pierce

Sets ten self-piercing rivets in one stroke while fastening two pieces of sheet steel for use in air conditioning duct work. Parts are loaded on a fixture which swivels into the riveting area.

Sound Dampening

A Model 800 rivet setter is equipped with a sound dampening enclosure and a lead screw powered programmable in-line shuttle fixture. One of two rivet patterns is selected by sensors, depending on the parts that are loaded. The shuttle allows the uniform riveting of a complicated assembly by simultaneously locating and holding all of the parts.

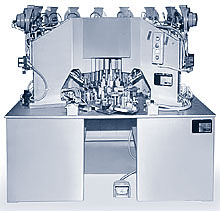

Automatic 3 Position

Five Model 1600 Riveters with an automatic 3-position slide fixture sets ten self-piercing rivets in an air conditioner panel assembly. Three rivets are set at first position, five at second position and two rivets at third position. Slide fixture then returns to load position away from the riveters.

Vibratory Bowl

A Model B is complimented with a vibratory bowl for feeding electrical contacts, and an automatic strip feeder for part placement. This fully automatic machine rivets at a rate of 90 parts per minute.

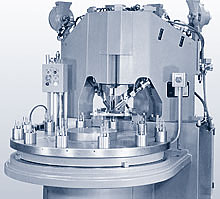

8-Station Index

One Model B Riveter over an 8-station 24″ diameter index table with part sensors at three stations and automatic air ejection.

8-Station Index Table

Two Model B Riveters over a 24″ 8-station index table, double tooled at each station to increase production. Variable cycle time to match operator performance.

Used & Retooled Rivet Machines

Looking for a cost-effective riveting solution? Think National Rivet! Explore our reconditioned machines or extend the life of yours with expert reconditioning.