Controlled Jaw Carriers

A standard feature of all National riveters is the Controlled Jaw Carrier. This National design improvement virtually eliminates head marking and rivet “spitting” by smoothly and efficiently delivering the rivet to the work. Less jaw tension is required thus decreasing abrasion wear as rivets pass through the jaws.

Overview

The Controlled Jaw Carrier is a real improvement over conventional riveters where driver force on the head of the rivet is required to lower the jaws to the work.

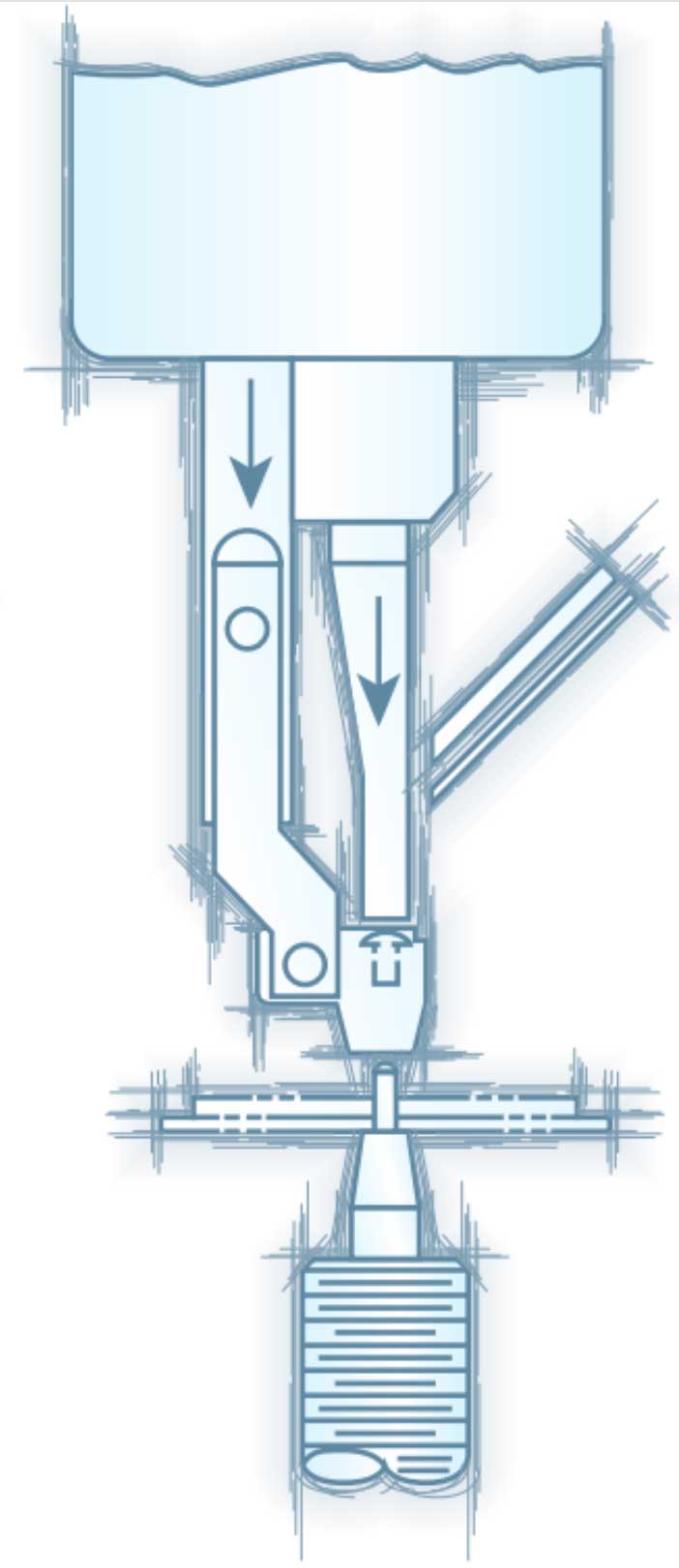

The sequential drawings below illustrate how the Controlled Jaw Carrier system works. All adjustments are accessible and easy to make. It’s another National feature designed to provide a higher level of efficiency and performance.

How It Works

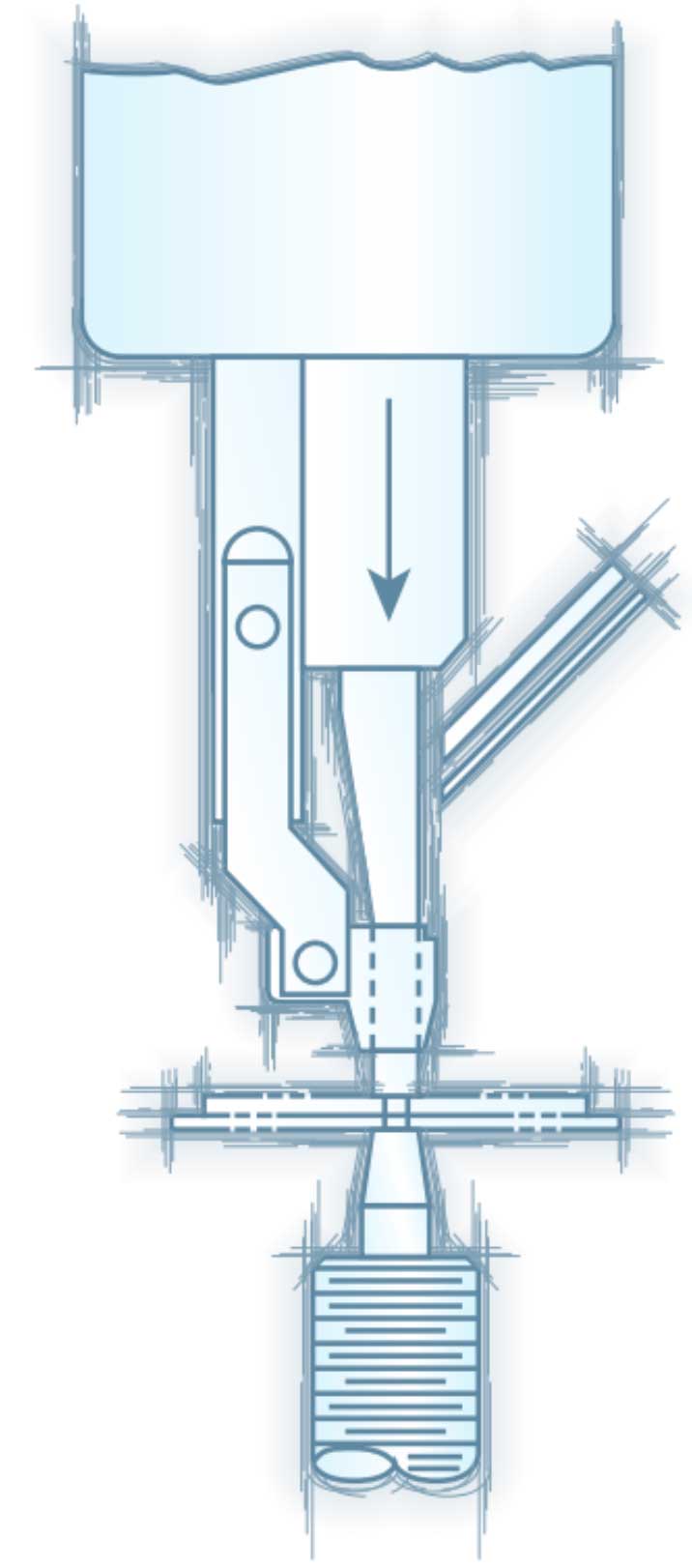

1. Normal home position – rivet resting in jaws.

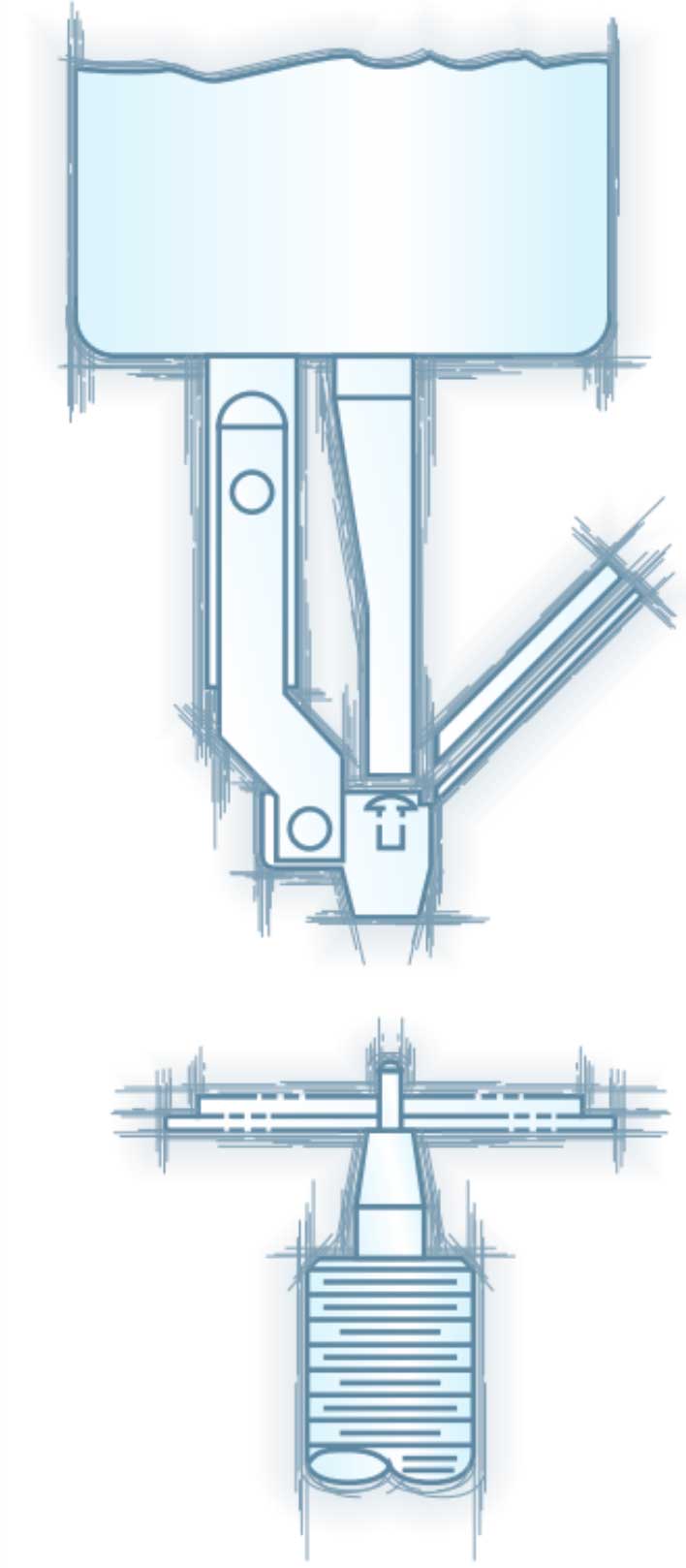

2. Driver moves down to trap rivet but does not touch head.

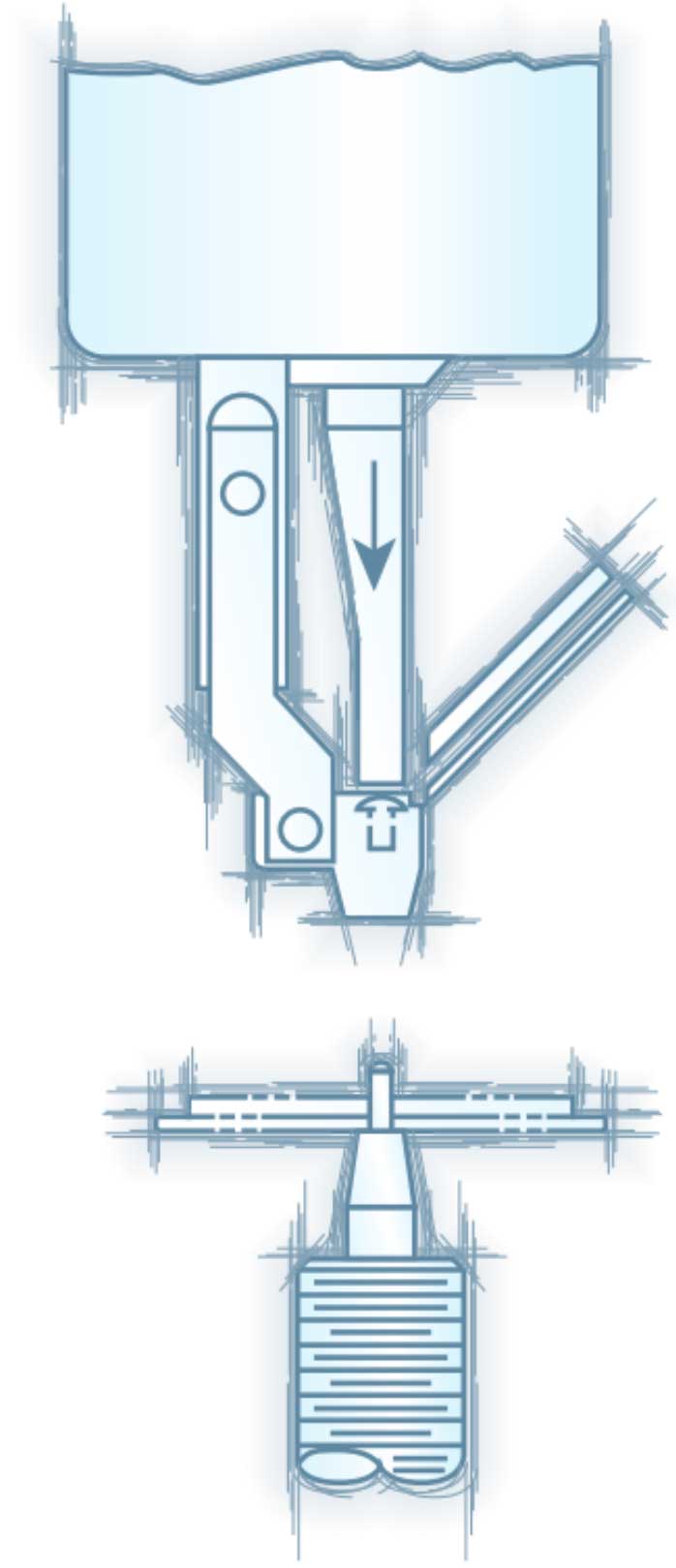

3. Driver and jaw carrier advance together toward anvil with no pressure on rivet head by driver.