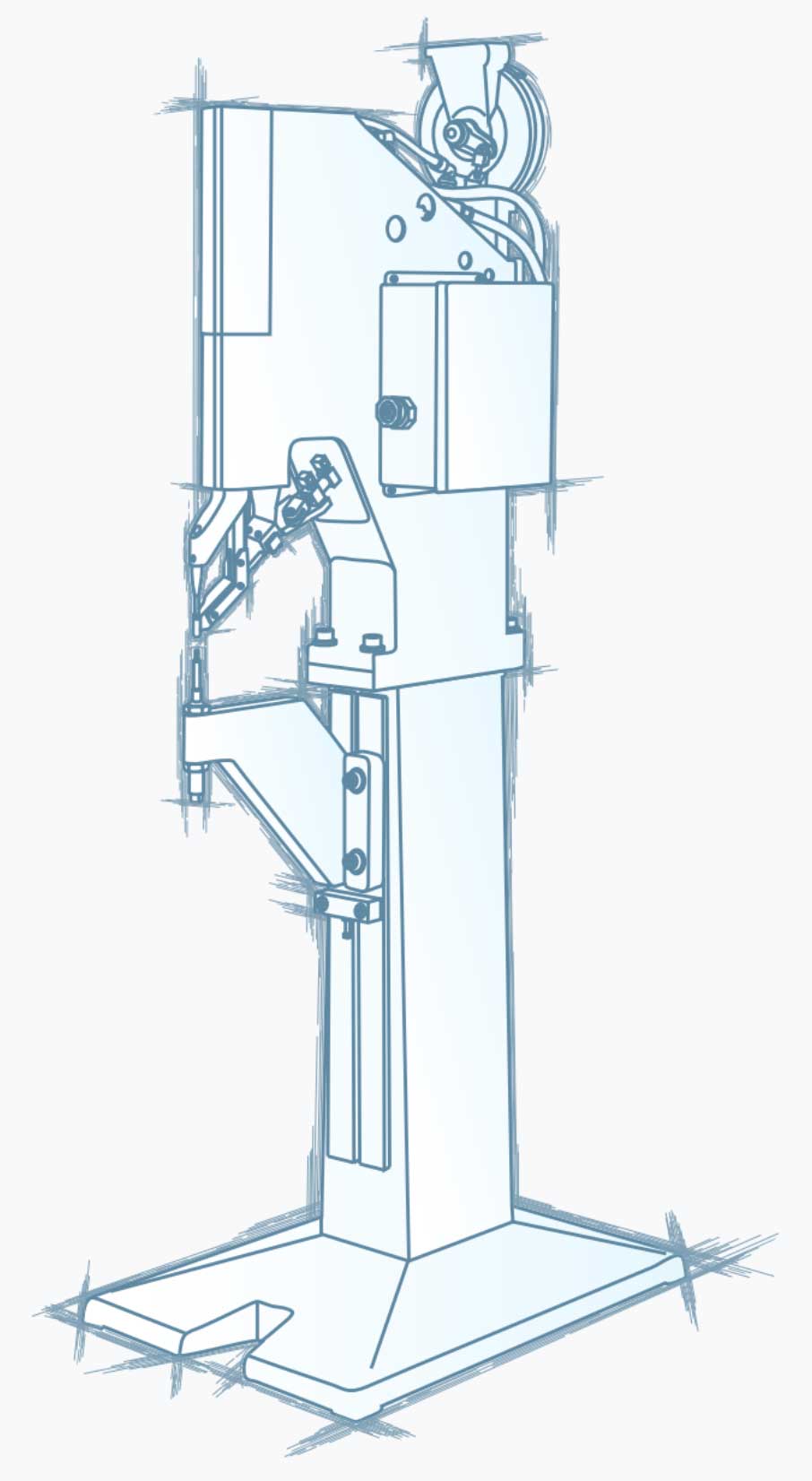

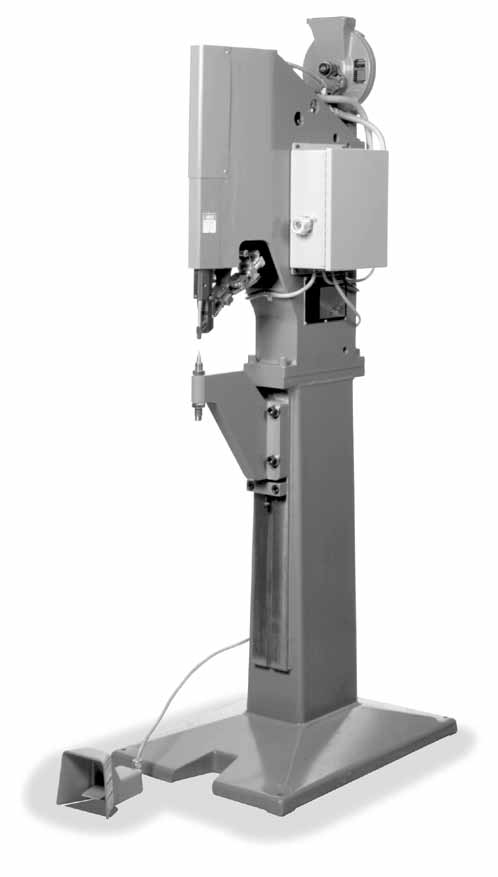

Model 1600 Pneumatic Machines

Features

In this series of machines, an air cylinder powered toggle link mechanism drives the rivet to a positive setting height as the links straighten out. An optional spring compensator can be built into the top pivot pin to accommodate varying work thicknesses.

The cycle time for these setters is about 1 second.

The Offset version of the 1600 is extremely versatile and will solve your clearance problems with parts, such as a rivet set close to a flange. This model can attach rivets inside cookware products, as well as in other awkward, hard-to- reach spots. Typical applications include school desk and chair assemblies, chimney caps and roof vents.

Each model can be customized to your specific needs and requirements.

Model 1600F

Model 1600F Offset

Model 1600F

Product Specs

Model 1600F Offset

Product Specs

Rivet Tools & Accessories

Investing in quality riveting accessories is a proven method for increasing efficiency. In fact, many people blame problems on their rivets or rivet setters, when the real culprit is worn or inadequate tools and accessories. As an integrated supplier, our engineers can quickly spot system deficiencies and recommend a new, more productive riveting solution.